Environmental Disaster Prevention Engineering Laboratory

The Environmental Disaster Prevention Engineering Laboratory provides education and research guidance on disaster mitigation technologies for natural disasters such as earthquakes, volcanic eruptions, and landslides, as well as man-made disasters such as fire, vehicle collisions, heavy chemical industrial plant explosions, and terrorism.

Main research themes: Disaster recovery support and Self-Defense Force, nitrogen gas test method for concrete, and design method for ultra-high-strength steel fiber reinforced-concrete beams that receive impact loads

Teaching staff

Main research themes

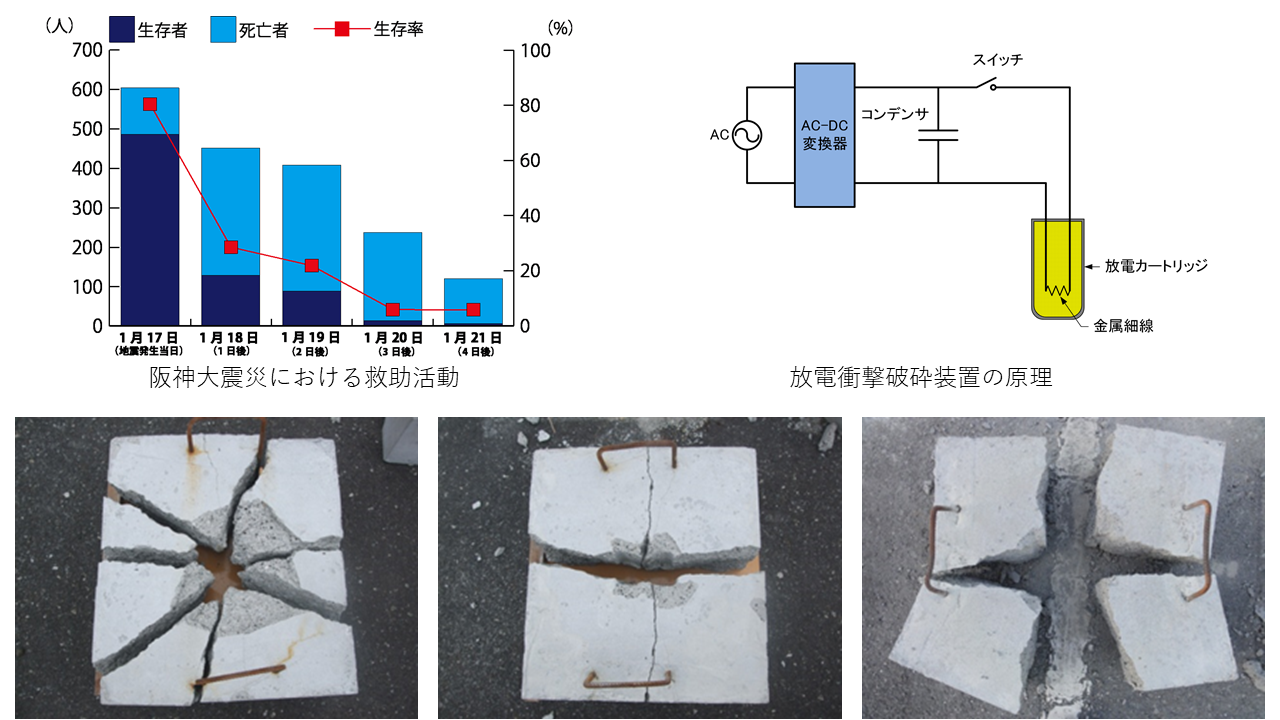

Development and application of controlled electrical discharge impulse crushing technology for saving lives during an earthquake disaster

It is important to rescue people trapped in buildings that collapse owing to powerful earthquakes within 72 h of the earthquake. To ensure access to quick rescue by removing debris, the application of the electrical discharge impulse crushing method is considered effective. As illustrated in the figure, in the electrical discharge impulse crushing method, the high-voltage energy temporarily charged in the capacitor of the electrical discharge impulse crusher is discharged in an extremely short time, which triggers the self-reactive liquid in the discharge cartridge to rapidly burn and generate a large crushing force similar to the explosion of an explosive device. In our laboratory, as a basic research for human rescue during an earthquake disaster, we are developing a technology to control the direction of crack growths in concrete that are triggered by electrical discharge impulse crushing.

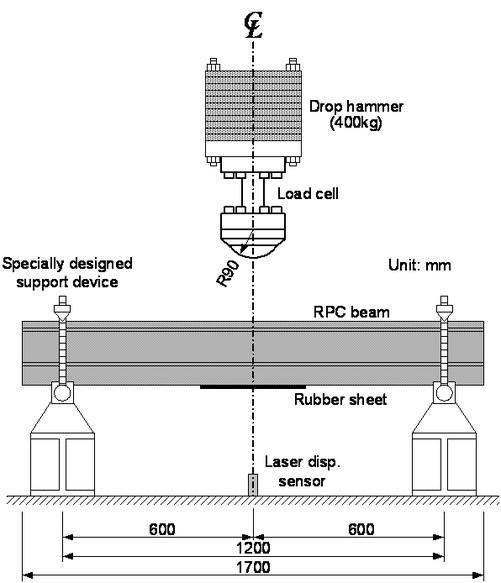

Design method for ultra-high-strength steel fiber reinforced concrete beams that receive impact loads

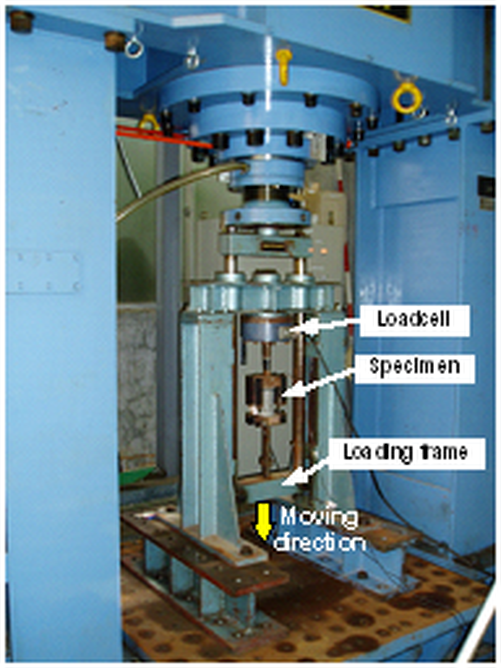

Ultra-high-strength steel fiber reinforced concrete (reactive powder concrete), which has a compressive strength exceeding 200 MPa, is expected to be applied to structures that are expose to impact loads, as a high-performance material with ultra-high strength and high toughness. In our laboratory, in addition to examining the impact characteristics of ultra-high-strength steel fiber reinforced concrete beams, we are developing a method to analytically evaluate impact behavior, using a configuration model based on the loading speed effect at the material level of the ultra-high-strength steel fiber reinforced concrete.

Nitrogen gas test method for concrete

In collaboration with a research group at the University of British Columbia (Canada), we are developing a novel strength test method for concrete. This test method harnesses the fact that when a concrete cylindrical specimen is placed in a steel cylindrical loading container with open ends, and an inert gas pressure is applied to the side surface of the concrete cylindrical container, the specimen will be axially fractured at a gas pressure approximately equal to the tensile strength of concrete. This test method has several advantages, such as inexpensive test equipment compared to the hydraulic loading equipment commonly used for concrete strength testing, and easy testing procedures, even at construction sites. In addition, this method does not require the end-surface treatment of the specimen. In this laboratory, we are currently conducting research on the elucidation of the fracture mechanism of concrete specimens via the novel strength test method.